Storm Heating/Cooling Work Station

Storm was designed as an add-on module for the Carousel 6 Plus and Tornado combination, creating a powerful ‘Parallel Process Reactor’. Storm heats and cools, and with the aid of an overhead stirrer, can mechanical stir up to 6 flasks (50 ml to 250 ml), making it the ideal process optimisation and development tool.

- When combined with a suitable circulator Storm is a powerful heating (+200 °C) and cooling (-65 °C) work station.

- Storm’s contoured top plate was design to specifically accept the Carousel 6 Plus and Tornado combination.

- Storm does not contain integral stirring (therefore stirring must be provided by a suitable overhead stirrer).

- Storm combines with the Carousel 6 plus, Tornado, overhead stirrer and a circulator to provide controlled heating/cooling and stirring for up to 6 flasks from 5 ml to 250 ml.

- Storm’s unique internal design maximises heat transfer from the circulator thermofluid, focusing the energy towards the top plate surface.

- The design minimises temperature variation across the contoured top plate.

- Storm is compatible with Huber, Julabo, Lauda and other leading brands of circulator (M24 connections required)

- Storm will accept thermofluid from -85 °C to +235 °C: providing a typical solution temperature within your reaction flask of -65 °C to +200 °C

- Storm’s insulated outer case reduces heat loss and prevents burns through contact with hot or cold thermofluid.

- An optional two-piece, removable PTFE insulating cover/plate provides increased energy efficiency when used with the Carousel 6, for improved heating and cooling.

- The insulating plate also helps reduce ice formation on exposed surfaces at sub-ambient temperatures.

- The 135 mm ø top plate will also accept Heat-On and similar reaction blocks

- Storm is ideal for temperature controlled, steady state reactions.

What is the difference between Storm and Breeze?

Storm

Features a sophisticated internal fluid path that combines with a high performance insulated case to maximise thermal transfer. These features create a temperature control module that has a wide operating range with excellent heat transfer, making Storm ideal for steady state reactions from -65 ˚C to +200 ˚C that require stable temperatures for extended periods, with minimal variation across the heated surface.

Breeze

Small bench-top footprint and no insulation; resulting in a narrower operating range of -30 °C to +165 °C. Yet because it is smaller, Breeze has a much faster response time to required changes in temperature. This makes Breeze more suitable for applications that require solution control such as crystallisation studies.

- Unique internal design focuses the thermofluid towards the top plate surface

- Fluoropolymer splash guard is chemical-resistant and prevents heat transfer from block to insulated outer case

- Insulated outer case ensures efficient operation with minimum heat loss and maximum safety

- M24 hose fittings (adapters available)

- Optional PTFE insulating plate provides increased energy efficiency for improved heating and cooling

- Contoured inner surface accepts Carousel 6 base precisely. Carousel 6 Plus locates on to the storm without tools

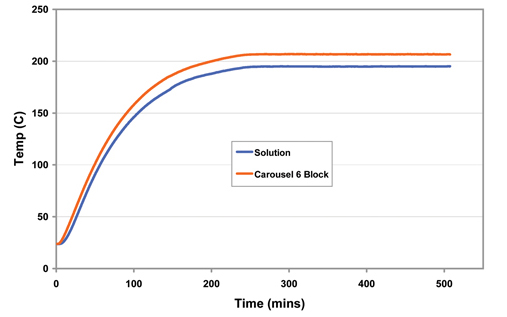

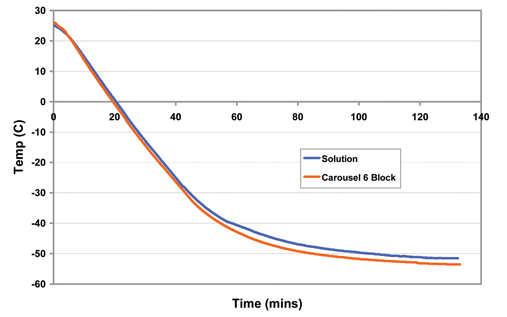

Typical cooling and heating profiles for Storm

Storm/Carousel 6 Heating Profile using a Huber 705

Storm/Carousel 6 Cooling Profile using a Huber 705