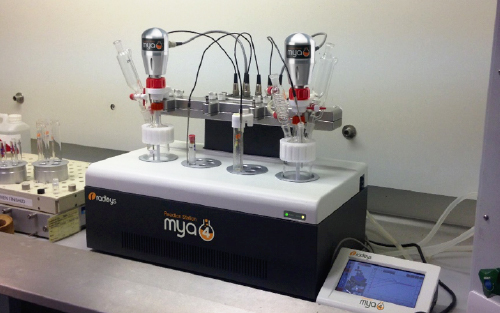

4 independent zones

-30 to 180 °C

2 ml to 400 ml

Magnetic & overhead stirring

Automation & data-logging

Control 3rd party devices

One of the best user friendly reactors available in different scales for rapid reaction screening and optimizationAbhishek Shrikant, Syngene International

Ideal for a wide range of applications

Process development

Design of Experiment (DoE)

Scale up

Route scouting

Polymorph screening

Biopharma research

Reaction optimisation

Lead optimisation

Crystallisation studies

Reagent, catalyst & solvent screening

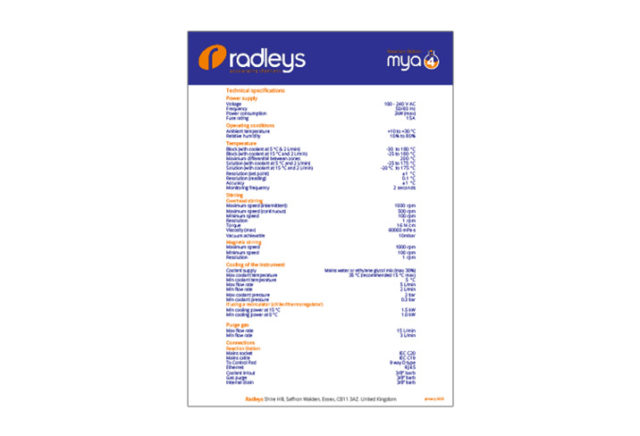

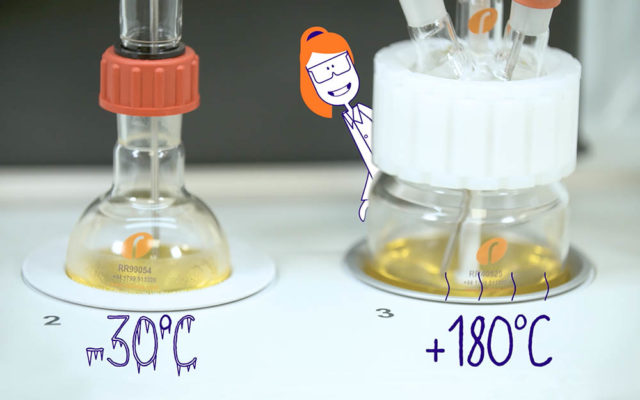

Temperature range

- Block temperature range -30 °C to +180 °C. Solution temperature range at least -20 °C to +150 °C. Independent control of each zone. Block or solution control

Wide range of vessels

- 2 ml to 400 ml. Vials, tubes, round bottom flasks and straight sided process vessels

Mya Compact Stirrer

- Powerful, high-torque overhead stirring. Tool-free attachment. Stirs from 100 to 1000 rpm. Control each position independently

Minimal zone cross-talk

- Up to 200 °C difference between adjacent zones thanks to high performance insulation. Ideal for multi-user work and multiple projects

Cool to -25 °C with tap water

- Powerful Peltier technology provides rapid cooling. No need for a separate chiller

Magnetic stirring as standard

- Control each position independently from 100 to 1000 rpm

Reflux or Manifold Head

- For efficient refluxing and distribution of inert gas. Reflux Head is water-cooled and used with reflux tubes. Manifold Head distributes water for glass condensers

Touch-screen Control Pad

- Supplied as standard. Intuitive and easy to use. Use manual control or set automated profiles

Optional PC Control Software

- Integrate and control 3rd party devices such as pumps, balances and pH sensors

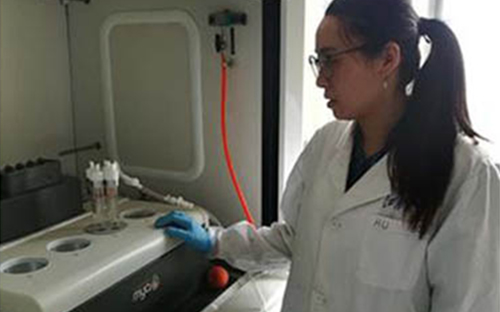

Excellent visibility

- Easily view your vessel contents

Space saving

- Compact benchtop footprint. Less space than 4 separate reaction set-ups

Single or multi-user operation

- Control heating/cooling and stirring of each zone independently

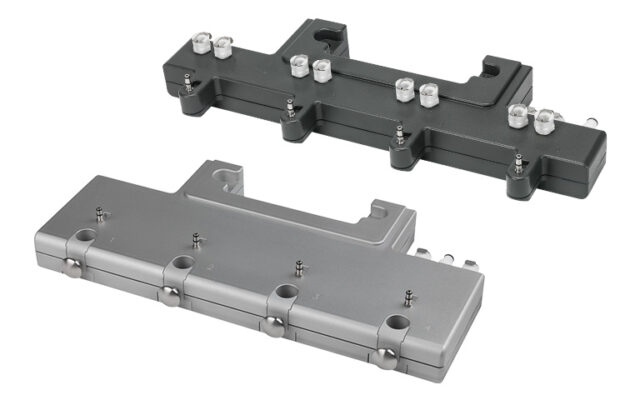

Manifold or Reflux head

- Water-cooled

- Distribute gas for inerting

- Manifold head:

- Distributes water for individual condensers

- With non-return shut-off valves

- Reflux head:

- Cools the outside of reflux tubes

- Efficient refluxing in a simple set-up

Magnetic or optional overhead stirring

- Integrated magnetic stirring – from 100 to 1000 rpm

- Optional overhead stirring with Mya Compact Stirrer

- Powerful, high torque motor

- Stirs from 100 to 1000 rpm

- Tool-free attachment

- Control the stirring speed of each position independently

- Use magnetic or overhead stirring in adjacent zones

Wide selection of vessel styles and volumes

Vials, tubes, round bottom flasks and process vessels from 2 to 400 ml

- Vials and tubes from 2 to 20 ml

- Round bottom flasks (from the Carousel 6 Plus range) from 25 to 250 ml

- Process reaction vessels from 50 to 400 ml

- Multi-neck glass lids – 3 or 5-neck

- Accessory Glassware

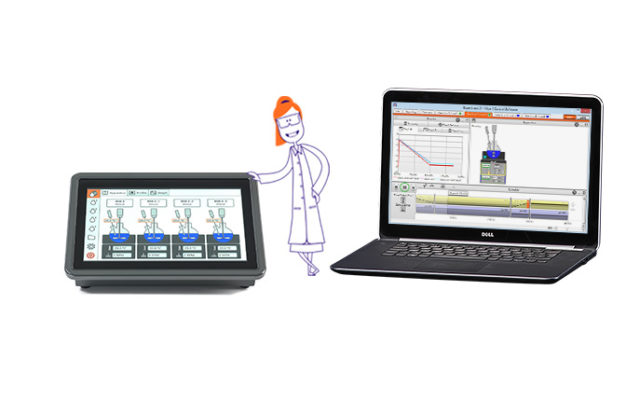

Software control and data logging

Choice of touch-screen Control Pad and PC Control Software.

Run experiments in manual or profile mode. Easily repeat profiles. Export CSV data.

- Touch-screen Control Pad – supplied as standard

- Optional PC Control Software – to integrate and control 3rd party devices

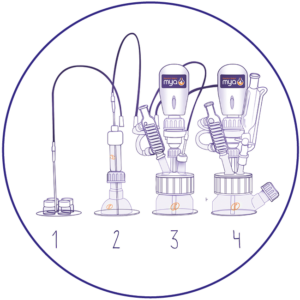

How to configure your Mya 4 system

Book an online demo with an expert

View calendar & bookMya 4 Options & Accessories

Webinar: Consistent Scaling Up

Scaling up chemical reactions can present a number of challenges with respect to efficient mixing, mass transfer, controlling exothermic reactions, heat transfer and reaction kinetics.

In this webinar we discussed some simple guidelines which apply when scaling chemical reactions up or scaling down to predict or reproduce conditions observed in the larger scale manufacturing environment.

Blog: Understanding and overcoming the challenges in chemical synthesis at a global CDMO

Andrew Kennedy and Jono West from Sai Life Sciences are interviewed about the work they do and how they utilise Radleys equipment in order to understand and overcome chemical synthesis challenges.

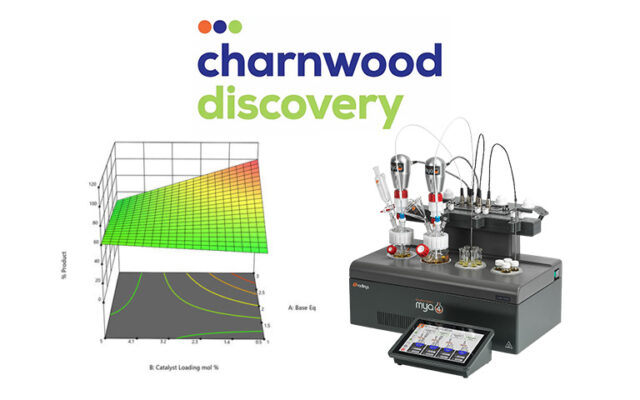

Webinar: Beyond the White Paper - How Purolite improved their process development with Mya 4

Based on a white paper on the same topic, Dr Patrick Gilbert from Purolite explains how his R&D group greatly improved their small-scale Process development and DoE work.

Data-led, this case study presentation shows you how this was achieved.

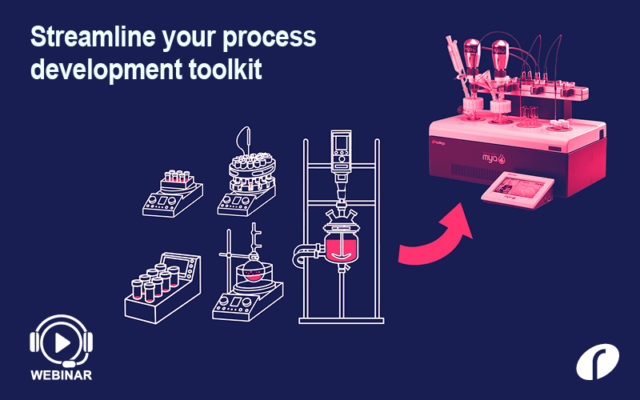

Webinar: Streamline your process development toolkit

When choosing the kit you will use for your Process R&D chemistry, there are many considerations to be made.

If you’re currently using hotplates, ice baths and jacketed reactors for your small-scale Process R&D chemistry, how could you consolidate this work with a single piece of equipment?

In this webinar we discuss the most common needs for process chemistry and introduce the Mya 4 Reaction station for screening reactions to small scale Design of Experiment.